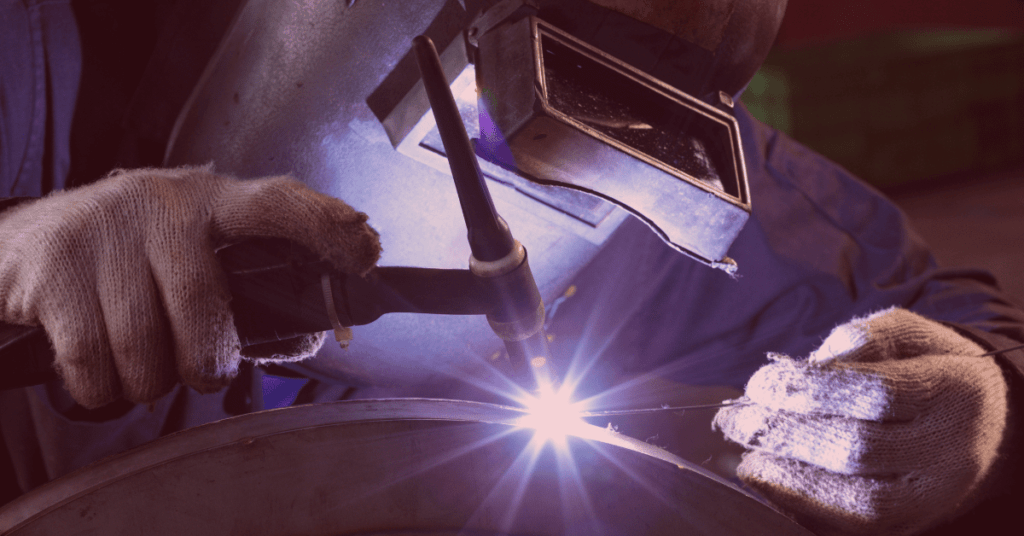

In the buying and purchasing industry, keeping everyone safe is very important. The people in charge, called procurement managers, have a big responsibility to make sure their teams are safe while also getting work done well. One thing that’s really important for them to have is leather welding gloves. These gloves help protect people from getting hurt while they’re working. In this article, we’ll talk about why leather welding gloves are so important for procurement managers and how they make the workplace safer and better for everyone.

Table of Contents

ToggleBenefits of Leather Welding Gloves

Protection Against Heat and Flames

Leather welding gloves are designed to withstand high temperatures, making them ideal for environments where heat and flames are present. The natural heat resistance of leather provides a barrier against sparks and flames, reducing the risk of burns and injuries.

Durability and Longevity

Leather is known for its durability, making it an excellent choice for welding gloves. Leather welding gloves can withstand regular use and are resistant to wear and tear, ensuring they last longer than other materials.

Enhanced Grip and Dexterity

Leather welding gloves offer superior grip and dexterity, allowing procurement managers to handle materials with confidence and precision. The flexibility of leather ensures that users can maintain a firm grip on objects without sacrificing comfort or mobility.

Comfort and Fit

Comfort is essential when wearing safety equipment for extended periods. Leather welding gloves are designed with ergonomic features to provide a comfortable fit that allows for natural hand movement. Additionally, the breathability of leather ensures that hands stay cool and dry, even during prolonged use.

Versatility in Applications

Leather welding gloves are suitable for a wide range of welding techniques, including MIG, TIG, and arc welding. They can also be used for various procurement tasks beyond welding, such as handling materials and operating machinery, making them a versatile choice for procurement managers.

Cost-Effectiveness

While leather welding gloves may have a higher initial cost than other types of gloves, they offer excellent value in the long run. Their durability and longevity mean that they need to be replaced less frequently, resulting in cost savings over time.

Factors to Consider When Choosing Leather Welding Gloves

Material Quality and Thickness

When selecting leather welding gloves, it’s essential to consider the quality of the leather and the thickness of the material. High-quality leather provides better protection and durability, while thicker gloves offer increased heat resistance.

Size and Fit

Proper sizing is crucial for ensuring maximum comfort and protection. Procurement managers should choose gloves that fit snugly without being too tight, with adjustable features for a customizable fit.

Heat Resistance

Procurement managers should look for leather welding gloves that meet specific heat resistance standards, ensuring they provide adequate protection against high temperatures commonly encountered in welding environments.

Comfort and Flexibility

Comfort and flexibility are essential for long-term wearability. Lined gloves provide added comfort, while flexibility ensures that users can perform tasks with ease and precision.

How Leather Welding Gloves Benefit Procurement Managers

Safety Compliance

Investing in leather welding gloves helps procurement managers meet occupational safety standards and regulations, ensuring compliance and protecting employees from workplace hazards.

Risk Reduction

By providing employees with the proper safety equipment, such as leather welding gloves, procurement managers can minimize the risk of workplace accidents and injuries, reducing liabilities and ensuring a safer work environment.

Enhanced Productivity

Leather welding gloves instil confidence in employees, allowing them to focus on their tasks without worrying about their safety. This confidence leads to increased productivity and efficiency in procurement operations.

Cost Savings

Preventing workplace injuries through the use of leather welding gloves can result in significant cost savings for procurement managers. By avoiding medical expenses, downtime, and potential legal fees, businesses can protect their bottom line and invest in their employees’ safety.

Maintenance and Care Tips for Leather Welding Gloves

Regular Inspection

Procurement managers should regularly inspect leather welding gloves for signs of damage or wear, addressing any issues promptly to ensure continued protection and performance.

Cleaning and Maintenance

Proper cleaning and maintenance are essential for extending the lifespan of leather welding gloves. Procurement managers should follow manufacturer guidelines for cleaning and conditioning to keep gloves in optimal condition.

Storage Guidelines

Storing leather welding gloves properly helps prevent damage and maintain their integrity. Procurement managers should store gloves in a dry, cool place away from direct sunlight and moisture to prevent deterioration.

Replacement Schedule

Knowing when to replace leather welding gloves is critical for ensuring ongoing protection. Procurement managers should monitor gloves for signs of wear and tear and replace them as needed to maintain safety standards.

Conclusion

In conclusion, leather welding gloves are indispensable safety equipment for procurement managers. Offering protection against heat and flames, durability, enhanced grip and dexterity, comfort, and versatility, these gloves contribute to a safer and more productive workplace environment. By investing in quality leather welding gloves and following proper maintenance and care practices, procurement managers can ensure the safety and well-being of their teams while also optimizing operational efficiency.

FAQs

Why are leather welding gloves essential for procurement managers?

Leather welding gloves provide essential protection against heat, flames, and workplace hazards, ensuring the safety of procurement managers and their teams.

How do leather welding gloves contribute to workplace safety?

Leather welding gloves help minimize the risk of workplace accidents and injuries by providing a barrier against heat, sparks, and other hazards commonly encountered in procurement operations.

What factors should procurement managers consider when choosing leather welding gloves?

Procurement managers should consider factors such as material quality, thickness, size, fit, heat resistance, comfort, and flexibility when selecting leather welding gloves for their teams.

How can procurement managers ensure the longevity of leather welding gloves?

Regular inspection, proper cleaning and maintenance, appropriate storage, and timely replacement are essential for extending the lifespan of leather welding gloves and maintaining their effectiveness.

What are the benefits of investing in quality leather welding gloves?

Investing in quality leather welding gloves offers benefits such as increased safety compliance, risk reduction, enhanced productivity, cost savings, and overall improvement in workplace safety and efficiency.